III

The Mont Cenis—The Fell Railway—The Great Tunnel Through the Alps

Guidebooks say that the pass of the Mont Cenis is dull. It is long, certainly, yet it has a fair proportion of picturesque points, and it is not easy to see how it can be dull to those who have eyes. In the days when it was a rude mountain-track, crossed by trains of mules, and when it was better known to smugglers than to tourists, it may have been somewhat dull; but when Napoleon’s road changed the rough path into one of the finest highways in Europe, mounting in grand curves and by uniform grades, and rendered the trot possible throughout the entire distance, the Mont Cenis became one of the most interesting passes in the Alps. The diligence service which was established was excellent, and there was little or nothing to be gained by travelling in a more expensive manner. The horses were changed as rapidly as on the best lines in the best period of coaching in England, and the diligences themselves were as comfortable as a “milord” could desire. The most exciting portion of the route was undoubtedly that between Lanslebourg and Susa. When the zigzags began, teams of mules were hooked on, and the driver and his helpers marched by their side with long whips, which they handled skilfully. Passengers dismounted, and stretched their legs by cutting the curves. The pace was slow but steady, and scarcely a halt was made during the rise of 2,000 feet. Crack! crack! went the whips as the corners of the zigzags were turned. Great commotion among the mules! They scrambled and went round with a rush, tossing their heads and making music with their bells. The summit was gained, the mules were detached and trotted back merrily, while we, with fresh horses, were dragged at the gallop over the plain to the other side. The little postilion seated on the leader smacked his whip lustily as he swept round the corners cut through the rock, and threw his head back, as the echoes returned, expectant of smiles and of future centimes.

The air was keen and often chilly, but the summit was soon passed, and one quickly descended to warmth again. Once more there was a change. The horses, reduced in number to three, or perhaps two, were the sturdiest and most sure of foot, and they raced down with the precision of old stagers. Woe to the diligence if they stumbled! So thought the conductor, who screwed down the brakes as the corners were approached. The horses, held well in hand, leant inwards as the top-heavy vehicle, so suddenly checked, heeled almost over; but in another moment the brake was released, and again they swept down, urged onwards by whip, “hoi,” and “ha” of the driver.

All this was changed. The Victor Emmanuel railway superseded a considerable portion of Napoleon’s road, and the Fell railway did the rest; and when the great tunnel of the Alps was opened for traffic, that brought about another change.

The Fell railway, which was open about four years, was a line that well deserved attention. Forty years earlier, Mr. Charles Vignolles, the eminent engineer, and Mr. Ericsson, patented the idea which became an accomplished fact on the Mont Cenis. Nothing was done with it until Mr. Fell, the projector of the railway which bore his name, took it up; and to him much credit was due for bringing an admirable principle into operation.

The Fell railway followed the great Cenis road very closely, and diverged from it either to avoid villages or houses, or, as at the summit of the pass on the Italian side, to ease the gradients. The line ran from St. Michel to Susa. The distance between those two places is, as the crow flies, almost exactly equivalent to the distance from London to Chatham; but by reason of the numerous curves and detours the length of the line was nearly brought up to the distance of London from Brighton. From St. Michel to the summit of the pass it rose 4,460 feet, or 900 feet more than the highest point of Snowdon is above the level of the sea; and from the summit of the pass to Susa, a distance less than that from London to Kew, it descended no less than 5,211 feet!

The railway itself was a marvel. For fifteen miles and three-quarters it had steeper gradients than one in fifteen. In some places it rose one foot in twelve and a half! An incline at this angle, starting from the base of the Nelson Column in Trafalgar Square, would reach the top of St. Paul’s Cathedral if it were placed at Temple Bar! A straight piece of railway constructed on such a gradient seems to go up a steep hill. One in eighty, or even one in a hundred, produces a very sensible diminution in the pace of a light train drawn by an ordinary locomotive; how, then, could a train be taken up an incline six times as steep? It was accomplished by means of a third rail placed midway between the two ordinary ones, and elevated above them.35 The engines were provided with two pairs of horizontal driving-wheels as well as with the ordinary coupled vertical ones, and the power of the machine was thus much increased. The horizontal wheels gripped the centre rail with great tenacity by being brought together, and were almost incapable of slipping, like the ordinary wheels when on even a moderate gradient.

The third rail was the ordinary double-headed rail, and was laid horizontally. It was bolted down to wrought-iron chairs, three feet apart, which were fixed by common coach-screws to a longitudinal sleeper, laid across the usual transverse ones. The sleepers were attached to each other by fang-bolts. The dimensions of the different parts will be seen by reference to the annexed cross section:—

For some distance from St. Michel the gradients were not unusual, and a good pace was maintained. The first severe piece was about two miles up, where there was an incline of one in eighteen36 for more than half-a-mile. The line rose at one step one hundred and sixty-four feet. Thence to Modane the gradients were again moderate (for a railway) and the distance—about ten miles and a half from St. Michel—is accomplished without difficulty in an hour. Modane station was 1,128 feet above St. Michel, so that on this easy portion of the line there was an average rise of 110 feet per mile, which is equal to a gradient of one in forty-eight; an inclination sufficiently steep to bring an ordinary locomotive very nearly to a halt.

Just after passing Modane station there was one of the steepest inclines on the line, and it seemed preposterous to suppose that any train could ascend it. When this was passed, the line mounted by comparatively easy gradients towards Fort Lesseillon. It was then at a great height above the Arc, and wound around the faces of the cliff out of which the Napoleon road was cut, looking down upon the foaming stream below. The next remarkable point was at Termignon. The track made a great bend, then doubled back, and rose in a little more than a mile no less than three hundred and thirty-four feet. This was, perhaps, the most striking piece of the whole line.

Lanslebourg station, 25½ miles from, and 2,220 feet above, St. Michel, was arrived at in two hours and a quarter from the latter place, and the railway then rose continuously to the summit of the Mont Cenis pass, accomplishing an ascent of 2,240 feet in six miles and a third of distance. It was curious and interesting to watch the ascent of the trains from Lanslebourg. The puffs of steam were seen rising above the trees, sometimes going in one direction, and sometimes in directly the contrary, occasionally concealed by covered ways—for over two miles out of the six the line was enclosed by planked sides and a corrugated iron roof to keep out the snow—and then coming out again into daylight. The zigzags of the old Cenis road are well known as one of the most remarkable pieces of road-engineering in the Alps. The railway followed them, and ran parallel to the road on the outside throughout the whole distance, with the exception of the turns at the corners, where it was carried a little farther out, to render the curves less sharp. Nevertheless they were sufficiently sharp (135 feet radius), and would have been impracticable without the centre rail.

The run across the top of the pass, from the Summit station to the Grande Croix station—a distance of about five miles—was soon accomplished, and then the tremendous descent to Susa was commenced. This, as seen from the engine, was little less than terrific. A large part of this section was covered in,37 and the curves succeeded one another in a manner unknown on any other line. From the outside the line looked more like a monstrous serpent than a railway. Inside one could see but a few yards ahead, the curves were so sharp. On emerging into the open air, one looked down some three or four thousand feet of precipice and steep mountainside. The next moment the engine turned suddenly to the left, and driver and stoker had to grip firmly to avoid being left behind. The next, it turned as suddenly to the right; the next there was an accession or diminution of speed, from a change in the gradient. An ordinary engine, moving at fifty miles an hour, with a train behind it, is not usually very steady, but its motion is a trifle compared with that of a Fell engine when running downhill.

The trains, however, ran smoothly, and this was partly due to the fact that each carriage was provided with a centre rail brake. The flat face A, and the corresponding one on the opposite side, were brought together against the two sides of the centre rail by the shaft B being turned, and they hold it as in a vice. This greatly diminished up-and-down motion, and rendered oscillation almost impossible. The steadiness of the train was still further maintained by pairs of flanged guide-wheels under each of the carriages, which, on straight pieces of line, barely touched the centre rail, but pressed upon it directly there was the least deviation towards either side.

The steam was shut off, and the brakes were applied, a very few minutes after beginning the descent to Susa. The train might then have run down for the entire distance by their own weight. In practice, it was difficult to apply the proper amount of retardation; the brakes had frequently to be whistled off, and sometimes it was necessary to steam down against them. Ordinarily, they went down with the steam shut off, and with the centre rail brakes screwed up moderately; and when a train composed of two or three carriages and a luggage-van was running down at the maximum speed allowed (fifteen miles an hour), the brakes could pull it up dead within seventy yards. The engines were also provided with centre rail brakes, on a pattern somewhat different from those on the carriages, and the flat sides which press against the rails were renewed every journey. A single run from Lanslebourg to Susa made grooves into them about three-eighths of an inch in depth.

The Fell railway was an experimental line, and as such it was a success. It reduced the time that was formerly occupied in passing from St. Michel to Susa by nearly one-half; it lessened expense and gave increased comfort to travellers. The gauge (3 feet 7⅜ inches) was a mistake, inasmuch as it lost time and caused trouble by the transference of the passengers, limited the power of the engines, and rendered the rolling stock unfit for general use, when the line was pulled up—which, according to the terms of the concession that was granted to the promoters, was done when the great tunnel of the Alps was opened for traffic.

When M. Medail of Bardonnêche—more than half a century ago—pointed out that a shorter tunnel could be constructed beneath the Alps between his village and Modane than at any other place in the Sardinian States having a similar elevation above the level of the sea, neither he, nor any other person, had the least idea how the project could be executed.

The first step was taken by the geologists Signor Sismonda and M. Elie de Beaumont. They predicted that calcareous schists and quartzite rocks would form a large proportion of the strata through which the tunnel would pass. It takes a miner one hour and a half to two hours to make an ordinary hole for blasting (28 inches deep) in calcareous schist, and not less than eight hours to make one 20 inches deep in quartzite.38 When would the tunnel have been finished if the ordinary processes had been alone employed?

The ordinary processes were clearly unavailable. The tunnel would be of prodigious length, and would have to be constructed without shafts. At no place where a shaft would have been of any use would it have been possible to make one less than 1,000 feet deep! If one had been made about midway between the two ends, it would have been no less than 5,315 feet deep. “I estimate,” says M. Conte,39 “that the sinking of a shaft a mile in depth would occupy not less than forty years. I do not know that a depth of 1,000 feet has been hitherto passed.”40

“Several projects were presented to the Sardinian government, some proposing to shorten the length of the tunnel by raising its level, and others to accelerate the boring of the holes for blasting; but they were all put aside as impossible, or as having been insufficiently studied. The first one seriously considered by the government was that of M. Maus, a Belgian engineer. He proposed to construct a tunnel of 12,230 metres between Bardonnêche and Modane, with a ruling gradient of 19 in 1,000. The advance of the small gallery in front was to be made by means of a machine with chisels, put in motion by springs, that would have cut the rock into blocks—leaving them attached only at the back—which were afterwards to be brought down by means of wedges.”

“M. Colladon of Geneva suggested moving the tools of the machine of M. Maus by means of compressed air, but he neither pointed out the means of compressing the air, nor how it was to be applied as a motive power.”

“The government had constructed the railway from Turin to Genoa, and engineers were studying how to tug the trains up the incline at Busalla, which has a gradient of 1 in 29. MM. Grandis, Grattoni, and Sommeiller proposed to compress air by means of the compresseur à choc which is now used on the works of the Cenis tunnel, and to employ it for the traction of the trains.”

“Mr. Bartlett, an English engineer on the Victor Emmanuel railway,41 had invented a machine for making holes for blasting, which was put in motion by steam. The machine was imperfect, and while experiments were being made with it (by means of compressed air), M. Sommeiller invented the boring-machine which is now used in the tunnel.”

“The problem then appeared to be solved. The inventors joined themselves to M. Ranco—who had taken part in their experiments on the Genoa railway—and prepared a scheme, after having found out that they could compress air to a high pressure, that this air could be led from closed reservoirs and transmitted to great distances without a sensible diminution of its pressure, and that it could be employed to move the boring-machine which was intended to make the holes for blasting. A commission was appointed to examine the project, and its members satisfied themselves that the scheme was feasible. The Act of , authorised the government to construct the section of the Victor Emmanuel railway between Susa and Modane, and MM. Grandis, Grattoni, and Sommeiller, were appointed to direct the works.”

“M. Medail indicated the general direction of the tunnel between Modane and Bardonnêche. M. Maus drew his line a little more to the east, nearer to Modane. The engineers who directed the work approached the latter course, and selected that which seemed to them to be the shortest, the most easy to come out at, and, especially, the most convenient to lay out.”

“It is needless to insist on the importance of the tracing of the course of the tunnel. It was necessary—1. To establish upon the mountain a sufficient number of marks in order to determine the vertical plane passing through the axis of the gallery; 2. To measure exactly the distance between the two mouths; 3. To determine the difference of level between the two mouths, in order to arrange the gradients of the tunnel. These delicate operations were entrusted to MM. Borelli and Copello. M. Grandis undertook the control of the work. … In the triangulations and levellings were undertaken, and they were terminated at the end of the year.”

On account of the peculiar situation of the ends of the tunnel, two small, connecting, curved tunnels had to be made. At first, “the construction of these terminal curves was naturally neglected for the establishment of the two false mouths in the direction of the general line.”

| “The length between the two false mouths is | 12,220.00 | metres. | |

|---|---|---|---|

| The entry on the side of Italy is at a height of | 1,335.38 | ” | |

| The entry on the side of France is at a height of | 1,202.82 | ” | |

| Difference of level | 132.56 | ” | |

| This difference of level is overcome by a gradient of 222 in 10,000, which rises from the French entry to the centre42 | = | 135.64 | ” |

| A gradient of 1 in 2,000, which rises from the Italian entry to the centre | = | 3.06 | ” |

| 132.58 | ” | ||

If a single gradient had ruled throughout, rising from the French to the Italian side, it would have been reduced to 217 in 20,000; but although this would have been of the greatest advantage in working the line, it would have added one more difficulty to the construction of the tunnel. There were enough difficulties without adding another.”

“It was, besides, evident that driving the tunnel to a summit doubled the chances of the two ends meeting, and negatived to a certain extent, the possibilities of error from the two operations upon which the least dependence could be placed—the triangulation and the levelling. Provided that the two axes were in the same direction, they were obliged to meet sooner or later; whether this happens a few yards more to the north or to the south is of no importance.”43

At the commencement of the tunnel, in , there was no accommodation at either end for those employed on the works; and for a long time both engineers and workmen had to submit to numerous privations. Roads had to be made, and barracks to be erected. One after another, houses and shops were added, and at the present time the tunnel-buildings alone form considerable villages at the two ends.44

The situations of the two mouths are essentially different from each other. That at Bardonnêche comes out at the bottom of the Valley of Rochemolles; that at Fourneaux 300 feet above the Mont Cenis road. At the latter end the debris has been shot out at the mouth down the mountainside; and, large as the tip (in the language of navvies) undoubtedly is, it is difficult to believe one sees all the material that has been extracted from more than two miles and a half of tunnel. It is interesting as showing the greatest angle at which debris will stand. Its faces have, as nearly as possible, an angle of 45°.

During four years the ordinary means of excavation were alone employed, and but 1,300 yards were driven. In this time the machines were being constructed which were destined to supersede a large part of the manual labour; at the beginning of they were sufficiently complete to be put to work, and in the summer of that year I went to Bardonnêche to see them in operation.45

The clocks of Oulx had just struck twelve on the night of the , as the diligence crawled into the village from Briançon, conveying a drunken driver, a still more intoxicated conducteur, and myself. The keeper of the inn at which we stopped declined to take me in, so I sought for repose in a neighbouring oatfield, and the next morning mightily astonished a native when I rose enveloped in my blanket bag. He looked aghast for a moment at the apparition which seemed to spring out of the ground, and then turning round in a nervous, twitching manner, dropped his spade and fairly bolted, followed by hearty shouts of laughter.

Bardonnêche was about an hour distant. A strange banging noise could be heard a long way off, and a few minutes after my arrival, I stood in one of the shops by the side of the machine which was causing it, and by the side of M. Sommeiller, the inventor of the machine. They were experimenting with one of his perforatrices, and a new form of boring-rod, upon a huge block of rock which was already riddled by more than a hundred holes, varying from one inch to four and a half in diameter. The perforatrice—a simple-looking cylinder fixed in a square frame, and connected with a few pipes and stopcocks—was placed in a fresh position in front of the rock, and, at a sign from the engineer, was set in motion. A boring-rod darted out like a flash of lightning, chipped out several fragments at a blow, and withdrew as quickly as it had advanced. Bang, bang, it went again with the noise of a gong. In ten seconds the head of the borer had eaten itself a hole; in a minute it had all but disappeared; in twelve it had drilled a hole nearly a yard deep, as cleanly as a carpenter could in a piece of wood. The rod not only moved backwards and forwards, and advanced as the hole grew deeper, but turned gently round the whole time. A jet of water, projected with great force, cooled the chisel, and washed out the chips. More air was turned on, and the sound of the blows could no longer be distinguished one from another. They made a continuous rattle, and the rate was increased from two hundred to no less than three hundred and forty strokes per minute, or about half as fast again as the motion of the piston-rod of an express locomotive when going sixty miles an hour.

On approaching the tunnel-mouths, the pipes were seen which conducted the compressed air for the working of these boring-machines. They are eight inches in diameter, and are supported by pillars of masonry. As these pipes (B), outside the tunnel, were exposed to constant variations of temperature—sometimes to as much as 54° F in a single day—it has been necessary to guard against their expansion and contraction. They have been fixed accordingly at stated intervals by means of iron rods, the lower ends of which are carried through the masonry and bolted to plates on the outside. The intermediate pipes are carried on rollers (D) on the tops of the pillars, and between each of the fixed points there was one pipe having an enlarged mouth—terminated by a cheek—which received the end (A) of the ordinary pipe. A circular pipe of leather (C) was secured to the cheek by means of a metal washer, and, pressed down by the compressed air on the end of the ordinary pipe, made the joint sufficiently airtight, although it did not hinder the advance or the retreat of the pipe. In the tunnel itself, where the temperature was not subject to such fluctuations, these precautions were not necessary, and the pipes were carried along the walls, supported by brackets, as far as the end of the finished work. Through these pipes highly compressed air was conducted, and was delivered at the end of the “advanced gallery” where the boring-machines were at work, with only a slight diminution in its pressure, notwithstanding the escapes which occurred at the joints.

On entering the tunnel one was struck by its size. The Italians, with a magnificent disregard of expense, or from regard to the future, constructed it with two pairs of rails, and with a footpath on each side. From the rails to the crown of the arch its height is just 20 feet, and its width is 26 feet 6 inches. It is almost everywhere lined with masonry; a small fraction only of the rock is left unsupported. Not observed, but nevertheless existing, is a covered way about 3 feet 4 inches high, and 4 feet wide, which is made in the floor of the tunnel between the rails. It is in fact a tunnel within a tunnel. Originally its dimensions were less, and it was intended merely as a subway in which the pipes conveying the compressed air might be placed, and as a drain. It was found convenient to enlarge its size, and after that was done—on at least one occasion—it served a purpose for which it was not originally intended. On the , a sudden fall of rock occurred, which killed several miners and imprisoned about sixty others who were at work in the advanced gallery. They were greatly alarmed, and expected to be starved; but at last one of them remembered this subway, and they escaped by its means. After that occasion the miners, knowing they had this exit, troubled themselves very little about éboulements.

During its construction, the temperature of the tunnel remained tolerably uniform throughout the year, although much higher in some parts than in others. On the occasion of my last visit in , the exterior temperature was 63½° F in the shade; a mile from the entrance it was 65°, and the mouth looked like the sun on a misty November day. At two miles the thermometer showed 70°, the atmosphere had become foul, and the mouth was invisible. In two hundred and fifty paces more, it had risen to 75°, the tunnel was filled with dense clouds of smoke, the light of an ordinary miner’s lamp could not be perceived at the distance of five or six yards, and respiration was difficult, for the atmosphere was vile. This was at the end of the finished work. Hence air was drawn by the pumping-engines at the mouth, for it was hereabouts that all the foul vapours naturally accumulated. The great vault was no longer overhead, and the way was reduced to a drift eight or nine feet wide and scarcely as much high, encumbered with wagons filled with debris, between which and the walls one could barely pass. In a hundred feet or so, we emerged—comparatively speaking—into a blaze of light. Two hundred greasy, smoky, but still light-giving lamps, hung from the walls. Drops of water flashed past them like gems. Two hundred men toiled at the enlargement of the gallery—bearded, grimy men, some on their backs, some on their sides, some working overhead, some half naked, some quite naked—all tapping laboriously at their mining-rods, and all perspiring profusely. The temperature had risen to 81½°. The multitude of the lights, the crowd of men, and the obscurity of the smoke, helped to make the tunnel look an immense size—in fact, at this part, in its rough, unfinished condition, it was sometimes little less than 30 feet high and 35 feet wide. Not merely was rock removed at the top and sides, to be afterwards replaced by masonry, but it was occasionally excavated for an inverted arch, which was placed wherever it was necessary. The temperature was, as nearly as possible, the same at the roof of the gallery as it was on the floor; for jets of compressed air were let off above. The work of the masons would otherwise have been unendurable.

There was a difference then of 18° F between the temperature outside the mouth and at the end of the finished work. In winter this difference was trebled or quadrupled. How much of the increase was due to the lights, men, and horses, and how much to the natural temperature of the rock? If the heat had increased in the tunnel, yard by yard, at the same rate as it does when descending into the earth, the temperature in its centre should have been about 90° higher than at its mouth. Although it was known that the rate of increase was much less than this, the actual rate was not known. I believe it is correct to say that not a single observation was made upon the natural temperature of the rock until after the advanced galleries met. Shortly after their junction was effected, at the end of , Signor F. Giordano (Inspector of Italian Mines) directed his attention to the question, and found that the highest reading he could obtain (near the centre of the tunnel) was 85.1° F. The temperature of the air at the same part was slightly above 86°.

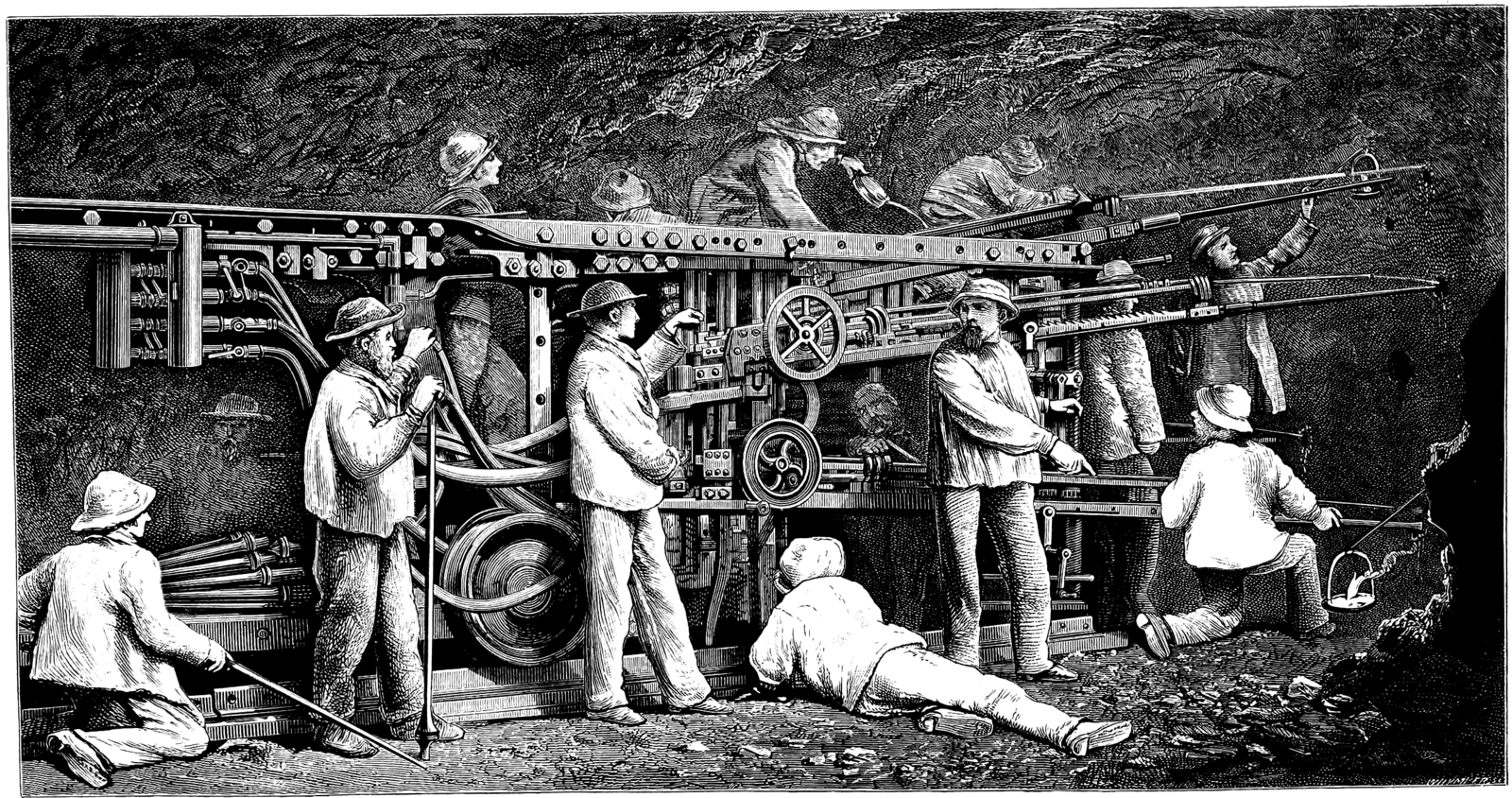

About 2,000 feet on the French side of the tunnel were undergoing the processes of enlargement and completion in the summer of . In some places portions of the advanced gallery remained untouched, and then one came to caverns, such as have been described above. This section was being completed faster than the advanced gallery was being driven. It was pleasant to get away from it farther into the bowels of the mountain; the heat became less, and the atmosphere more pure. The noise of the hammers died gradually away, and at last no sound could be heard, except of our own footsteps and of water running in the subway. After a time the banging of the chisels could be distinguished which were at work on the front of the attack. Five hundred paces took us to them. The ponderous frame, technically called l’affût, supported nine of the machines known as perforatrices; each perforatrice propelled a boring-rod, and each boring-rod was striking the rock at the rate of 200 strokes per minute, with a force of 200 pounds.46 The terrific din that these 1,800 strokes per minute, given with such force, make in a rock-chamber that was only 8 ft. 3 in. high, and 9 ft. 2½ in. wide, can hardly be imagined; neither can an adequate idea be given of the admirable manner in which the machines accomplished their work. In spite of the noise and the cramped position in which the men necessarily toiled on account of the limited space, the work went steadily forward day and night. Each man knew his part. The foremen directed by signs rather than by words; the labourers guided the chisels; the workmen regulated the supply of air; the machinists were ready in case of accident; slim boys, with long-nosed cans, oiled the machinery. Order triumphed in the midst of apparent confusion. One saw the results of years of perfecting and of practice. Things were very different at the beginning, when everything was new both to the workmen and engineers.

The best form of boring-rod for all kinds of rock, excepting such as are homogeneous, was hit upon in , and it was always used afterwards.47 The head had the form of a Z. For homogeneous rock, the ordinary form of chisel was found best. Almost all the details of the machinery, the size of the gallery, the dimensions and number of the holes, and the manner of firing them, were changed since the beginning; the general principles alone remained unaltered. The system latterly adopted was as follows. A hole 4¾ inches in diameter was made to a depth of about a yard, towards the centre of the drift, but rather nearer to the floor than to the roof. Fifty to sixty holes, according to circumstances, of less diameter, but of about equal depth, were then driven into the remainder of the face. All the holes were then dried and cleaned by jets of compressed air, the affût was withdrawn behind strong iron-bound doors, and six of the small holes nearest to the large were charged and fired. The force of the explosion went in the direction of least resistance, which was towards the central hole, and a breach was made such as is indicated in the longitudinal section, given below, by the thick dotted line. The remaining holes were then charged and fired in sets of six or eight at a time, those nearest to the breach being exploded first. This system was found more economical than firing a larger number of shots at one time. The wagons were then advanced, and the debris was cleared away; the two pairs of rails at the sides, shown in the cross section, were for wagonets, whose contents were afterwards transferred to large wagons. The affût was then again advanced. These operations were repeated with unvarying regularity twice every day.

The temperature at the working face of the advanced gallery was seldom higher than from 75° to 76°, and the atmosphere was as pure as could be desired, when the machines were at work.48 This, notwithstanding the presence of more than thirty men,49 and almost as many lamps, in a space about nine feet wide, eight high, and fifty long. The comparative lowness of the temperature was of course due to the expansion of the compressed air.

At the distance of a hundred and sixty paces, the sound of the machines could not be distinguished, and the atmosphere again gradually deteriorated as we returned to the region which might, not improperly, be termed infernal. Once more we passed through the foul vapours and the army of miners, engaged on the work of enlargement. Laborious as the work of these men undoubtedly was, it was lighter and far less dangerous than that of our coal-cutters. The heat, although it seemed considerable to one coming from a lower temperature, was not excessive. The miners worked readily enough for their three francs a-day,50 and took to their labours cheerfully; very few skulkers were seen in the Mont Cenis tunnel. The following table shows how small was the risk to life.

Fatal Accidents which occurred at the Great Tunnel of the Alps from the commencement of the works to (French side only):—

| Inside the Tunnel. | |

|---|---|

| From falls of rock | 8 |

| Accidents from wagons | 14 |

| Premature explosions | 3–25 |

| Outside the Tunnel. | |

|---|---|

| Falls from heights | 2 |

| Accidents from wagons | 4 |

| Explosion of gunpowder | 5–11 |

Total. 36

Nearly one-half of the fatal accidents arose from men being run over by wagons. This chiefly came from the impossibility of making the miners walk on the footways at the sides of the tunnel. They would walk on the rails. The result was that they were not unfrequently killed, although the greatest precautions were taken with the wagons descending with debris. The total is insignificant when one considers the number of men engaged and the length of time over which it was spread, and it compares favourably with almost any other enterprise of similar magnitude.

The wagons laden with debris ran down, on the French side, by their own weight, on account of the gradient, and so did the truck on which I descended with my guide—the courteous engineer who directed the works. Fresh relays of miners were entering, and those whom they relieved were coming out with their arms around each others’ waists “in the manner of schoolboys and lovers.” The air seemed chilly, although it was a bright summer day; and our nostrils, for hours after leaving the tunnel, yielded such supplies of carbon as to suggest that the manufacture of compressed soot might have been profitably added to the already numerous industries of the works.

In about four thousand men were now employed on the tunnel,51 and they completed ten to eleven feet every day. The average daily progress of the preceding five years was ten feet one inch. Each yard of progress cost latterly about £200. The total expenditure amounted to about £3,000,000 (£224 per yard). This sum, however, included the expense of the whole of the machinery and of the exterior works. The amount does not seem extravagant when we remember that for every yard of advance, never less—and frequently more—than seventy cubic yards of rock had to be excavated, and to be carried away (when the work was approaching completion) a distance of three miles; that about twenty-five cubic yards of masonry had to be built, the stone for which was conveyed twelve miles in a mountainous country; that all the machinery employed was constructed and invented expressly for the tunnel, and that the creation of two small towns was necessary.

The strata which were pierced agreed very satisfactorily in their nature and in their thickness with the indications of the geologists.52 Remarkably little water was met with: the miner’s dreaded enemy seemed to fly before the engineer who utilised its power. I have not entered into a description of the manner in which this was accomplished, because it has been frequently done by others; but there was nothing more interesting in regard to the tunnel than the way in which the waste powers of nature were applied for the reduction of the difficulties of the undertaking. There was not a single steam-engine on the works; everything was done with compressed air, or by hydraulic power.

Just one half of the tunnel was driven at the end of , after more than nine years of labour. The third quarter was finished by the end of , and upon the the junction of the advanced galleries was successfully effected. The engineers shook hands through a hole made in the centre of the drifts, and then blew away the narrow wall which separated France from Italy.53

Four weeks before this took place, the men who were employed in the advanced gallery on the French side heard distant rumbling sounds, and leaving off work, could distinctly hear their comrades firing blasts in the other gallery. At this time the two parties were about 400 feet distant from each other. As the interval which separated them lessened, so the excitement of the engineers became more and more intense. What if the two ends should not meet! At last the calculated length of the tunnel (12,220 metres) was excavated, but still the galleries did not meet! The two parties knew from the sounds of the shots that they were very close to each other, and they proceeded with the utmost caution. Several trying days of suspense passed before the happy moment arrived, and then it was discovered that there was an error of 44½ feet in the calculated length. This did not, however, cause any inconvenience. The work was pressed forward with increased assiduity, and on the the masonry was completed, the rails were laid, and the tunnel was ready for use. It was formally opened on . The inaugural train of twenty carriages, drawn by two of the largest and most powerful locomotives ever built, conveying 500 gentlemen, who had assembled together by invitation from all parts of Europe, left Turin at 6:30 a.m. and after a run of three hours and three-quarters arrived at Bardonnêche. A brief halt was made here, and then the train proceeded through the tunnel to Fourneaux (Modane). The passage through occupied twenty-two minutes. At Modane, a number of distinguished persons entered the train, whose length became increased to twenty-four carriages. This monster train started from Fourneaux to return to Bardonnêche at 12:30 p.m., drawn by two locomotives, and pushed behind by a third one. The return passage of the tunnel occupied forty-two minutes. At Bardonnêche a sumptuous banquet was given, to which about 700 persons sat down; and, after it was over, the company returned to Turin.

From the first, very little inconvenience was experienced from the imperfect ventilation of the tunnel, and the temperature at its centre was by no means oppressive. In the shade at Bardonnêche, before the first run through was made, the thermometer registered 69° F. The maximum heat in my carriage when passing through was 78°, and a quick-acting mercurial maximum thermometer, which I fixed on the outside of the carriage, registered only 77.1°. The steep gradient on the French side reduced the pace of the train on the return journey, and the thermometer outside the carriage registered 82°. Inside, however, 78° was, as before, the maximum heat.

It is difficult to apportion the credit of bringing this great work to a successful end amongst those who were engaged upon it. From the commencement to the termination Grattoni and Sommeiller were at the head of the enterprise, and upon them its chief responsibilities rested. They designed (sometimes separately, but more usually jointly) the whole of the machinery that was employed, and they gained the chief rewards. Grattoni lived to receive the highest honours. His friend and coadjutor Germain Sommeiller, exhausted by work, retired to his birthplace, St. Jeoire en Faucigny, to obtain a little rest. It was taken too late; he succumbed to his labours, and died at the comparatively early age of fifty-six years, on the . “If we may believe the companions of his youth,” said M. Conte, at the conclusion of the pamphlet from which I have already quoted, “Sommeiller cherished the idea, which we now realise, at the time he was studying at the University of Turin. This idea he never abandoned.” Englishmen ought to be amongst the first to recognise his boldness and perseverance, although they played no part in the execution of the tunnel. It is the grandest conception of its kind; it must always be one of the highways of Europe; and it has become an important portion of the high road to India.